CTBM: making renewable biogas from agri-food industry waste

The CTBM transforms organic matter into biogas using an industrial bioreactor.

From: DEC - April 25, 2024

Summary |

|---|

| Organization: Centre de traitement de la biomasse de la Montérégie (CTBM) (Website in french only) Number of employees: 22 Region: Montérégie Program: Regional Economic Growth through Innovation (REGI) CED’s support has made it possible to: acquire and install new equipment for the biomethanation, drying, and biofertilizer manufacturing processes, in addition to covering engineering and project management fees. |

Transcription

The video opens with a board with “CED X CTBM” and bright white logos on it. In the centre of the screen, a wide view of the CTBM’s facilities appears, including mainly two cylindrical digesters similar to agricultural silos and a bubble covered with a grey membrane used to gather the biogas. The aerial view gradually focuses in on the two digesters. The voice of Benoit Paré, President and Chief Operating Officer, is heard:

“- The Centre de traitement de la biomasse de la Montérégie (CTBM) is a business that processes organic materials from agri-food.

Benoit Paré appears in a close-up. He is in the machine room that controls the two digesters. Several pipes criss-cross the space behind him.

- We are talking primarily of milk byproducts, cranberry slurry, degraded alcohols unfit for consumption.

A series of images appears: the CTBM’s sign, a truck arriving on site and stopping on the scale, several aerial views showing basins containing liquids discharged by the trucks, and several trucks at work on the site. Benoit Paré continues to explain.

- The target is to recover organic materials to reduce the environmental and energy footprint by processing them onsite. Having an installation in Saint-Pie is interesting because the region is at the heart of Quebec’s foodshed and so is surrounded by generators of food materials.”

The camera continues to follow the truck as it arrives at the CTBM’s site. After the scale, the truck moves towards the security gate and goes through to the other side of the barrier. The following view shows the same truck on the security cameras, as a person verifies the data transmitted by the scale. A new voice, that of Louis-François Brodeur, Manager at the Governmental Affairs Directorate at CED, is heard:

“- Here, there are trucks from across the region that come with organic waste. Here, we recover this waste.

Louis-François appears on the screen, also from the machine room.

- The CTBM represents 140,000 tonnes of recovered waste, meaning a reduction of 12,000 tonnes of greenhouse gases. This is significant.

The camera is now in the CTBM’s laboratory, where Benoit and Louis-François examine samples of different products obtained from processing the slurry. Benoit continues to explain:

“- During our initial contacts with CED, a real chemistry developed between the two parties, because CED was really interested in innovation and is a collaborator who enabled us to acquire equipment for the new plant. Often, it is a major issue to have access to liquid assets.”

Aerial views of the CTBM follow before Louis-François Brodeur reappears on the screen:

“- It is important for it to be easy for entrepreneurs to come and see us, and then for us to look at what their needs are, and then for us to be able to meet their needs. We are here to accompany clients as they implement their projects.”

The aerial views focus in on the ground, and we see the tall grasses move as the wind blows into the mics. Benoit and Louis-François walk along the CTBM’s facilities, then observe the liquids in the basins. In another view, a female worker at the plant gathers a sample. Benoit continues:

“- The CTBM processes materials that, in the past, were considered as waste, and today they become a raw material. The biomethanation process is a bit like what happens in the human body. We ingest different ingredients, they are slowly processed, and then we emit three byproducts: a solid, a liquid and sometimes gases, so this is how materials are transformed.

Benoit is now on the screen and ends his analogy with a wry smile. The tour of the plant then continues for Benoit and Louis-François, who observe the operation of the dryer that transforms the solid part of the slurry into compost.

- For example, we make renewable natural gas, we will make organic fertilizers in the form of compost and liquid fertilizers also.”

The video returns to Louis-François in the machine room:

“- The Government of Canada has set ambitious targets for itself to reduce greenhouse gases, and when CED becomes involved here, we are doing our part to reduce greenhouse gases in Canada.”

Benoit explains the distinction between fossil gas and renewable natural gas. An animated sequence supports his explanations.

“- Fossil gases emit greenhouse gases, so a gas that is considered a pollutant. In fact, fossil gas was produced as materials decomposed in the soil over millions of years, so it is a single-use product because it takes a long time (to break down) and we use it only once, while renewable gas from food materials that we break down and return to the environment as a gas that will be reabsorbed by plants that, in turn, produce fruits, vegetables and animal food that, in turn, will be broken down, this is a renewable cycle. In our plant, we will consume on site a portion of the renewable gas we produce for thermal processes, and the rest will be injected into a distribution network that belongs to Énergir.”

Louis-François resumes speaking:

“- The CTBM is a wonderful example of a circular economy. When CED becomes involved in a project such as this one, we demonstrate that a biomethanation project is possible and can be reproduced on a larger scale, and this is something we are proud of.”

The camera then shows several CTBM employees completing maintenance work and daily operations. Then Benoit speaks of the pride he feels towards his team, as portraits of smiling employees appear on the screen:

“- One great source of pride for us at the CTBM is to see the growth with our employees, because when you enter the CTBM, you can imagine it is not a golf course, it does not smell of roses…. In the past, we had about five employees and we processed a few thousand tonnes per year; since then, we have increased production by a very significant factor, and we are now at about 20 people on site; they are passionate, they are invested in the process, and this is what makes the team strong here at the CTBM.”

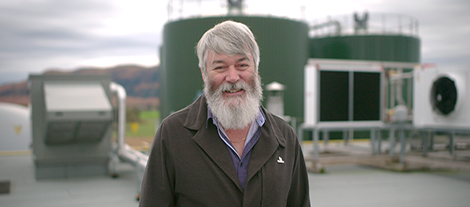

The camera then shows a close-up of Benoit standing on the CTBM’s roof. He slowly turns his gaze towards the sky to support his statements brimming with hope. The camera follows his gaze, and the music signals the end of the capsule.

The image is replaced by a green board that says: “SMEs, contact our business offices to build your green projects,” along with CED’s web address, ced.canada.ca. This is then replaced by a black board with CED’s departmental signature, followed by another black board with the Canada wordmark on it in white. This is then followed by the Government of Canada’s musical signature.

In operation for some 20 years now, the Centre de traitement de la biomasse de la Montérégie (CTBM) is a business that specializes in the processing of agri-food materials. When it was created, the CTBM focused on processing liquid materials and therefore had to dispose of the solid waste that resulted from this process.

In 2017, the CTBM launched a major investment project to acquire new equipment that would enable it to also process solid materials, including to transform them into renewable natural gas. Today, the CTBM produces compost, organic fertilizers, and renewable natural gas from over 100,000 tonnes of agri-food materials it receives every year. Redirecting these materials from landfill is equivalent to eliminating 12,000 tonnes of greenhouse gas (GHG) emissions thanks to the CTBM’s processing activities.

Renewable natural gas, a biomethanation product

Renewable natural gas is a natural gas with a much shorter processing cycle than fossil gas that comes from the decomposition of organic materials captured in the soil several millions of years ago. To obtain this gas, bacteria are used in an oxygen-free environment to break the organic materials down in a process that is similar to human digestion. The decomposition of organic materials generates a biogas that, once refined, is processed into biomethane.

Contrary to fossil gas, which emits GHGs given its origin, biomethane used for energy purposes discharges carbon that is absorbed rapidly into the environment by plants that are then eaten by animals. These same plants and animals, once processed by the agri-food industry, will provide the raw material needed for a new biomethanation cycle. According to regulations in Quebec, it is expected that, by 2030, 10% of the gas distributed through the Énergir network will come from renewable energy sources. Businesses such as the CTBM will make it possible to reach this target, by injecting their production into the network.